- -$0.50

Reference: DWM14042301

Spring antenna is specialized for wireless data transmission. This antenna with good performance of V.S.W.R, small size design, easily installation, stable performance and good anti-shock and anti-aged compatible for Hoperf Modules.

Reference: DWM14032902

SMA rf antenna connector is pallets copper gold andexternal thread needle sma pallets plate rf connector.

Reference: DWM14032102

Whip antenna for sub-1 GHz, 433MHz,868MHz and 915MHz with SMA male connectors.it's used with wireless module recommanded by Hoperf .

Reference: DWM14042401

SMA RG178 extension female cable for GPS, GSM antenna,RF module, SMA cable,IPEX to SMA jumper cable.

Reference: DWM18032302

USD3.0/pcs MOQ100pcs LoRa Antenna designed for Lora application which required for outdoor waterproof highgain and work at ISM free band like 433MHz /868MHz /915MHz SMA Male Whip antenna.

Reference: DWM16121503

DWM-TLB-3.0QB SUB-1GHz / 2.4GHz Whip antenna with a Collapsible SMA male connectors.Which are available for 433MHz,868MHz.915MHz and 2.4GHz..

Reference: DWM15101001

Brand: Semtech

RFM50 module series’ design is based on the high performance RF50 SoC chip, It include a CIP-51 core‘ MCU and 100mW transceiver. It operate at 433/470/868/915 MHz ISM band, comply with FCC, ETSI regulation.

Reference: DWM15010504

Brand: Semtech

The RFM69CW /RFM69HCW are built in by SX1231and SX1231H which is ISM Free band transceiver module capable of operation over a wide frequency range, including the 433MHz,868MHz and 915MHz.

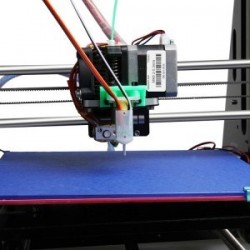

3DTouch features simple, smart and precise. It could work with nearly any kind of bed materials, such as glasses, woods, metals and so on.

3DTouch can be easily applied, since it has a small and simple structure. Gathering information & firmware setting will be an easy task, because 3DTouch works as usual auto bed leveling sensor.

Self-test: The push pin is operated three times to test when the power is on Alarm: The LED light blinks if a problem found on a self-test or on an operation

3DTouch’s Standard Deviation in repeatability is around 0.005mm, at that precise. If you choose 3DTouch, your 3D printer will be high-class masterpiece, giving you an enjoyable experience.

On idle state, while the push-pin is whether pulled out or retracted, there are not any electric current flowing on solenoid, and standby electric current in the whole device is below 15mA on average, whereas on working state, while the pin is moving in sudden about 100ms, under 300mA flows in the device. Low power consumption even further drops joule heating, preventing from heat problem.

3DTouch consists of Atmel ATtiny13A, solenoid, and a push pin.

3DTouch does not uses either optical, nor proximity (inductive/capacitive) sensor. 3DTouch is controlled by Hall Effect, providing high precision. Thus the bed material can be selected freely.

3DTouch is a small and technology-intensive one. Build size can be set larger than other existing auto bed leveling sensor.

3DTouch uses existing RC Servo motor signal intactly, so just plug 3DTouch on the same pins after removing servo motor.

For more detailed information, please refer to wiki.

Voltage: 5V

Current: 15mA

Max. Current: 300mA

Cable length: 150mm

Net Weight: 10g

Shipping weight: 25g

3DTouch can be operated in the following condition.

One I/O for control (PWM or Software PWM)

One I/O for Z min (Z Probe)

GND and +5V power

3-pin: Brown (-, GND), Red (+5V), Orange (control signal)

2-pin: Black (-, GND), White (Z min)

Caution

Additional power supply will be needed in case your board does not supply enough amperage.

Electronic devices can be damaged or even destroyed if connected to wrong polarity. [wrong terminal connect to 5V(+) and GND(-)]

Pulling/pushing hard on the push-pin can damage 3DTouch and make it less accurate.

Fix push-pin with locking paint after reassembling or adjusting core.

Do not remove or deform elastic material attached on the push-pin.

1 X 3DTouch Auto leveling sensor

1 X 3Pin Straight Pin

1 X 2Pin Straight Pin

2 X Screw & Nut & Washer

2 X Dupont Housing Shell 3Pin

2 X Dupont Housing Shell 2Pin

3 X Dupont Housing Shell 1Pin

14 X Dupont Terminal

1 X 10KΩ 1/8W Resistor

3DTouch auto leveling sensor User Manual.pdf

3DTouch auto leveling sensor-1.zip

3DTouch mount for Geeetech prusa I3 pro X.zip

Reference: DWM16092101

This is an modified MK8 extruder, which features outstanding quality and ensures better performance for 3D printers.

Reference: DWM16092101

This is an modified MK8 extruder, which features outstanding quality and ensures better performance for 3D printers.

Reference: DWM16092103

DWM- A4988 StepStick Stepper Driver Module lets you control one bipolar stepper motor at up to 2 A output current per coil.

3DTouch features simple, smart and precise. It could work with nearly any kind of bed materials, such as glasses, woods, metals and so on.